Water Treatment Plants:

THE PROPER CONTROL OF HUMIDITY PROBLEMS KILLS CORROSION, CUTS COSTS

In a water treatment plant, it goes without saying you want all the water running inside the pipes.

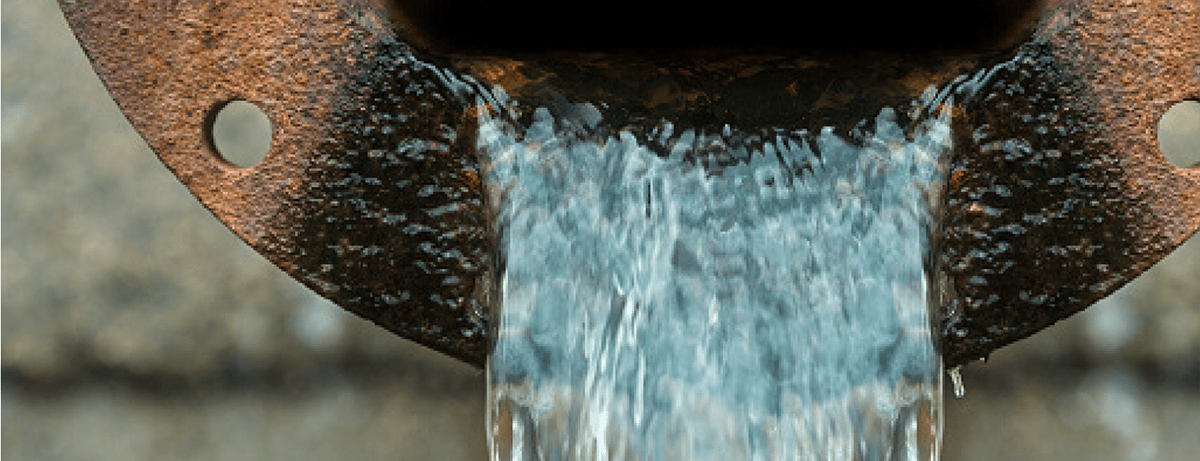

But 20 years ago, Rick Adamson, general manager for the Adams County Regional Water District, was dealing with a problem he never expected: Water – and tons of it – condensing and pouring off the outside of pipes inside a new, state-of-the-art facility in Manchester, Ohio.

The problem: Warm, humid summer air was blanketing pipes filled with cool ground water, which caused unwanted water to condense throughout the facility.

“We had never thought about dehumidification, but when we brought this plant online and had more room and a bigger building, it just looked like rivers running through the plant with water going everywhere,” Adamson said. “I thought the Ohio River was running through the plant.”

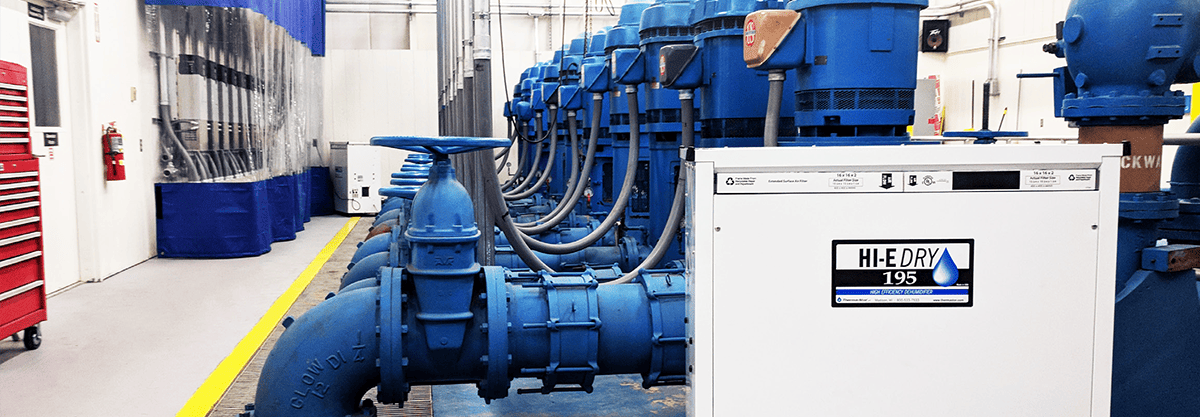

With a new $3 million plant online in 1999, serving about 7,500 taps, Adamson knew he had to find a solution – and quickly. The answer: Four Quest Hi-E Dry 195 Dehumidifiers placed throughout the plant. The result was a dry plant, nearly zero maintenance and thousands of dollars saved.

While Adams County Regional Water District quickly found a solution, many other districts and municipalities in the Midwest remain plagued with humidity problems in their water treatment plants – issues they’re currently trying to solve with much more costly and cumbersome methods than dehumidification.

Midwest moisture problems.

In and around the Midwest, particularly in states such as Michigan, Ohio, Pennsylvania and Wisconsin, high humidity is a costly and time-consuming hazard when not managed appropriately. But before digging into those issues, it helps to understand why humidity and moisture are significantly more problematic in the Midwest than, say, the South, where it’s equally as humid.

For starters, most water treatment plants in the Midwest pull their water from underground. In the South – and many other parts of the U.S. – drinking water is pumped from surface sources such as lakes and ponds. That matters because ground water is consistently 55 degrees or cooler, while surface water is much warmer, said Walt Waetjen, product manager for Quest Dehumidifiers.

When the cool ground water makes its way into a water treatment plant during late spring, summer and early fall months, when humidity is high, water quickly forms on pipes, floors and other surfaces.

“A beer can sitting on a bench outside is the perfect analogy,” Waetjen said. “The beer is below 50 degrees and the dewpoint on a warm day is above 50 degrees so the beer can sweats.”

And in the Midwest, most plants aren’t air conditioned, Waetjen said. With 20,000-gallon tanks of open water, coupled with thousands of feet of pipes it will be “literally raining,” without humidity control, he said.

And when that problem hits, it doesn’t take long for corrosion to take hold.

corralling corrosion in Water Treatment plants.

For Adams County Regional Water District – and all similar plants – the primary concern tied to high humidity is pipe corrosion. If condensation and high humidity go unchecked, pipes will rust at a rapid rate.

Without humidity control, plant employees have to sand rust, paint pipes and replace bolts on an annual basis, a drain on resources and budget.

“It’s costly because of the labor, especially if you use an outside firm to do it,” Adamson said. “You’re buying paint, buying bolts and then have to pull guys from another job and can’t have them doing something else,” Adamson said.

Preventing that corrosion is the primary reason for controlling humidity, Adamson said. Since installing his Quest Hi-E Dry 195 units in 1999, the need for painting is almost nonexistent because they can easily keep relative humidity at 40 percent during the hottest months of the year.

“The Hi-E Dry 195 units have been in there for almost 20 years and we haven’t had to do a whole lot of maintenance,” he said.

dripping water can cause concrete floors to pit and break up, while consistently high-humidity levels can cause sensors to malfunction.

Waetjen added that corrosion prevention goes beyond the pipes. Dripping water can cause concrete floors to pit and break up, while consistently high-humidity levels can cause sensors to malfunction.

DEHUMIDIFIERS save dollars.

When Adamson began to look for a solution to his water treatment humidity problem, he turned first to his team of engineers that built the plant. The estimated cost was $50,000 for a large rooftop unit – a cost Adamson wasn’t eager to cover.

Luckily, a consultant Adamson knew recommended Hi-E Dry 195 dehumidifiers. After a quick chat with a factory rep, four units were on their way to Adams County Regional Water District with the promise that if they didn’t work, he could return them and Quest would cover all costs.

“In 30 days I told the board, ‘you may as well cut the check, because these things are doing the job’,” Adamson said.

Adamson had an initial savings of more than $35,000.

Some of those cost savings also come in the form of the Hi-Dry 195’s reliability. Adams County had its original four Hi-E Dry 195 units for 20 years before recently ordering four new ones. All they ever had to replace were filters, Adamson said. And Adams County isn’t alone. This case study from Wisconsin highlights just how long a Quest dehumidifier can run.

Aside from reducing initial capital costs, using dehumidifiers cuts the need to paint annually, a cost savings of about $8-10,000 each year for most water plants, Waetjen said.

from slippery to safe.

While some water treatment plants aren’t staffed regularly, many, such as Adams County Regional Water District, have an employee onsite 24/7 to ensure everything runs smoothly. For that reason, safety is an increasingly important issue for plant managers.

Waetjen said that high levels of humidity in a water treatment plant can cause electrical panels to arc, which puts staff at risk of electrocution or shock. Additionally, a humid plant leads to other safety issues, such as shattering lightbulbs.

Of course, the most notable safety risk is a slippery floor. Adamson said since installing his Hi-E Dry 195s, it’s rare to find a wet spot on the floor and when they do it’s never because of humidity issues.

“It makes it a lot more comfortable working in there. Those dry floors mean a lot, Adamson said. “From a safety standpoint, you don’t have a situation where someone can slip and fall.”

Published on Jun 06 2022

Last Updated on Feb 16 2024

Categories: Agriculture, Climate Control, Dehumidification, Growing Cannabis