Reheat is reheat, no matter how you slice it.

Dan Dettmers

Senior Application Engineer

Debunking the Reheat Controversy: Why Efficient Dehumidification Matters for Growers

In the competitive cannabis industry, efficiency and precision are vital. One term that’s sparking both interest and confusion is “reheat.” As indoor agriculture adopts more advanced climate control systems, growers are hearing about reheat more often—but what does it really mean, and how does it affect your bottom line?

Dan Dettmers, Senior Application Engineer at Quest Climate, simplifies it: “Reheat is reheat, no matter how you slice it.” So, let’s cut through the noise and clarify how reheat works, its relationship to dehumidification, and how Quest’s energy-efficient systems can boost productivity and save money.

With modern systems, you don’t need to waste energy and money to reheat air.

Dan Dettmers

Senior Application Engineer

Understanding Reheat: It’s Not That Complicated

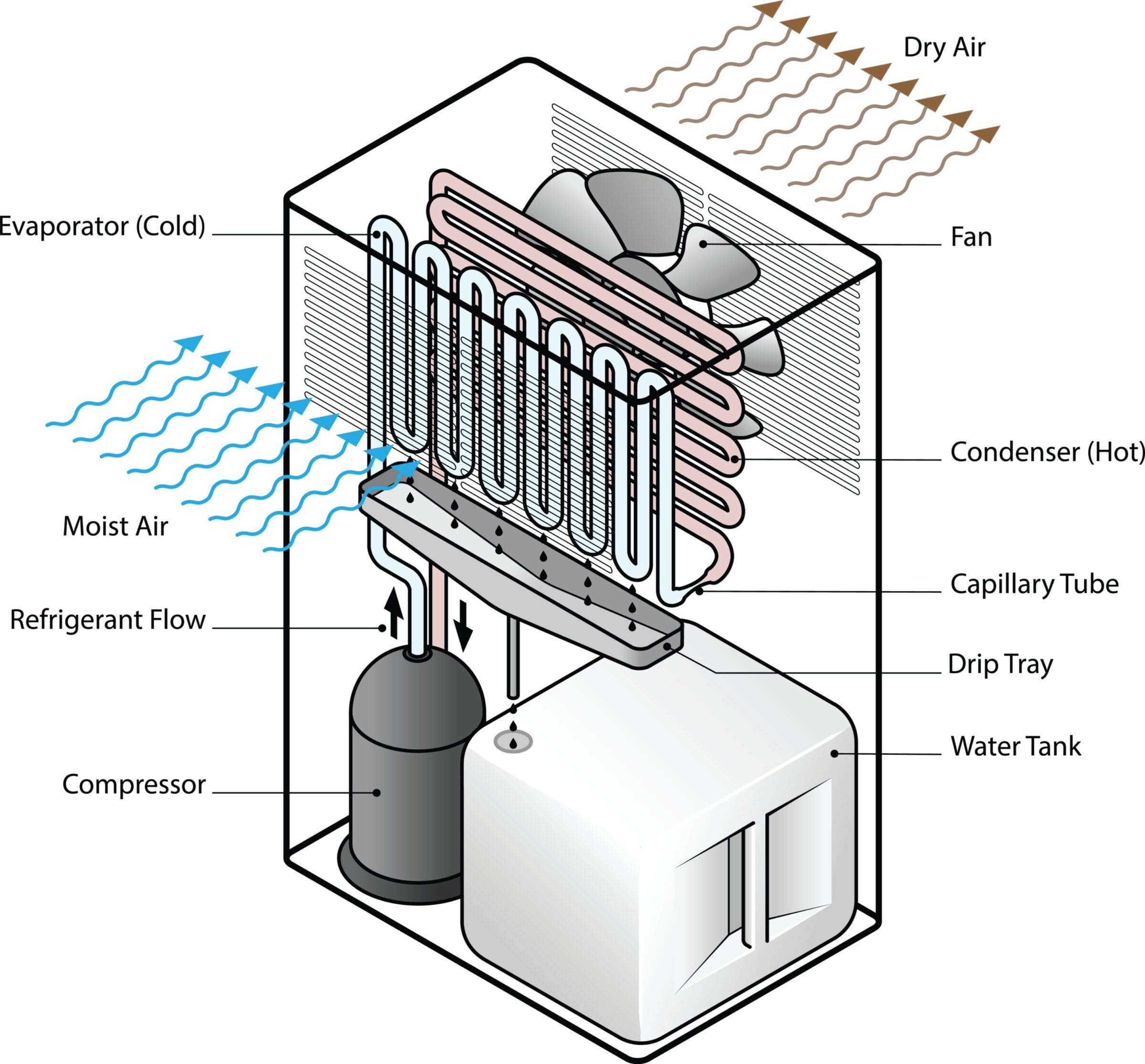

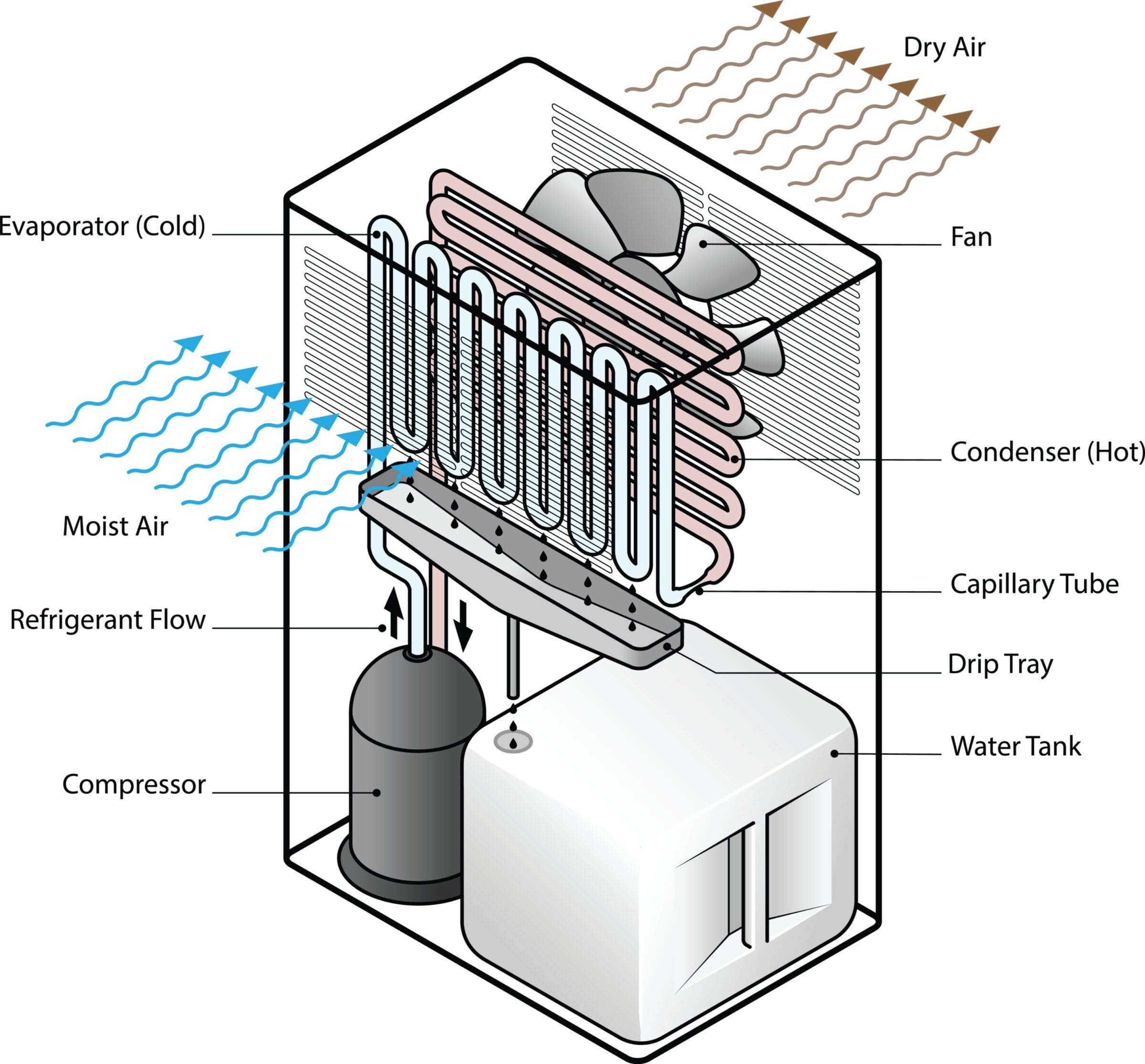

Reheat isn’t a new concept. It’s been part of HVAC systems since the early, inefficient days of air conditioning and dehumidification. An air conditioner can over-cool air to remove moisture, but the air is too cold for the people and plants in the space. To fix this, we would warm the air back up using heat generated by a furnace, boiler, or electric resistance. It took energy to cool the air and even more energy to reheat it back to comfort conditions. It worked well enough when energy was cheap, and there weren’t better options.

But things have changed. Today, systems like Quest’s dehumidifiers control humidity efficiently by recovering the reheat energy from the dehumidification process.

“With modern systems, you don’t need to waste energy and money to reheat air,” explains Dan. “Quest’s technology ensures that the air is efficiently managed, reducing both energy use and costs.”

The question isn’t whether you need reheat, it’s how you do it efficiently.

Dan Dettmers

Senior Application Engineer

Why Efficient Reheat Matters for Growers

Humidity control is everything in a grow room. Without proper dehumidification, you risk exposing your crops to mold, mildew, and other pathogens that can quickly ruin an entire harvest. Here’s the catch: to dehumidify the air, the air must first be cooled to wring out the humidity. But this air is often too cold for your grow room. It must be warmed up to keep the plants happy.

“The question isn’t whether you need reheat, it’s how you do it efficiently,” says Dan. “In grow rooms, reheating is necessary when the lights are off and the space cools down. But you need to reintroduce heat without wasting energy.”

Quest’s dehumidifiers are specifically designed to remove moisture and re-heat the space using the heat that was already removed, ensuring precision without the volatility associated with retrofitted A/C systems or the excessive energy cost of electric resistance. In grow environments where tight climate control is critical, this precision can make the difference between a thriving crop and a disastrous one.

Quest dehumidifiers offer precise control and are 5 to 20 times more efficient than traditional systems.

Dan Dettmers

Senior Application Engineer

Reheat Coils vs. Quest’s Dehumidifiers: What’s the Difference?

You may have heard the term “reheat” or “hot-gas reheat coils” used for retrofitting rooftop air conditioning units. But these systems weren’t originally designed for dehumidification.

“These rooftop units are built for air conditioning, not continuous dehumidification,” Dan explains. “Cramming a hot gas reheat coil into an air conditioner to imitate the function of a dehumidifier is like strapping a truck bed onto a Prius and calling it a pickup. Sure, it might work for limited applications, but that’s not what it was designed to do.”

A rooftop unit with a hot gas reheat coil will dehumidify the air, but it is very inefficient and difficult to control. Instead of the multiple stages of control offered by dehumidifiers, the rooftop unit can only offer “on” and “off.” This leads to wide swings in room relative humidity.

“Quest dehumidifiers offer precise control and are 5 to 20 times more efficient than traditional systems,” says Dan. “Using a rooftop to control your grow room humidity is using a flamethrower to light the candles on a birthday cake.

In short, serious grow operations require systems designed specifically for their needs. Quest’s dehumidifiers are engineered to manage moisture and temperature with maximum energy efficiency.

Purpose-built dehumidification systems, like Quest’s, do exactly what they’re designed to—remove humidity efficiently and effectively.

Dan Dettmers

Senior Application Engineer

The Cannabis Connection: How Reheat Impacts Your Bottom Line

Growing cannabis isn’t just about producing beautiful plants; it’s about running a profitable business. With rising energy costs and increasing pressure to operate sustainably, having efficient systems isn’t just helpful—it’s essential.

“Whether you’re a small grower or running a large facility, you’re in the business of making money,” Dan points out. “And if you want to maximize profits, you need to control energy costs and optimize for high production.”

Many growers mistakenly opt for hot gas reheat or electric resistance systems because they seem like quick solutions. But over time, these systems guzzle electricity, driving up energy bills and cutting into profits. By choosing Quest’s purpose-built dehumidification systems, growers can reduce costs while improving efficiency.

“You need the right tools for the job,” says Dan. “Purpose-built dehumidification systems, like Quest’s, do exactly what they’re designed to—remove humidity efficiently and effectively.”

For growers, this translates to healthier plants, higher yields, and significantly lower energy costs.

Reheat is only as efficient as the energy source you’re using

Dan Dettmers

Senior Application Engineer

Debunking the Myths: Reheat Is Reheat

There’s a lot of misinformation around reheat in the cannabis cultivation space. Some growers believe they can simply run their air conditioners harder and add a hot gas reheat coil to manage humidity and temperature conditions. While this approach might seem like a solution, it’s highly inefficient and not designed for the demands of a grow room.

In order to remove humidity, the air must pass over a surface colder than the dew point to condense water from the air. The colder the surface, the more water can be pulled from the air.

“Dehumidifiers are designed to easily reach low dew point conditions unachievable from A/C,” says Dan. Standard A/C units and rooftop systems are built to cool for comfort, with a limited ability to lower air temperatures sufficient for proper dehumidification. They aren’t designed to tackle the heavy dehumidification needs of a grow room. Dehumidifiers, on the other hand, can drop air temperature far below the dew-point, pulling more moisture from the air and creating dryer conditions.

The most efficient method to reheat air in a grow room is by recycling the heat from the cold coil of a dehumidifier and putting it back into the space. Simply adding a reheat coil to a rooftop unit is both ineffective and inefficient because it wasn’t designed for this task.

Even worse than an ineffective coil is using a new energy source to provide the reheat. Burning natural gas in a furnace, firing up a boiler, or spinning your meter by using electric resistance does not make sense. Why pay to cool the air and then pay again to heat it back up? “Reheat is only as efficient as the energy source you’re using,” says Dan.

Quest dehumidifiers are purpose-built for these conditions, ensuring optimal energy efficiency and precise climate control without relying on energy-hogging rooftop units or electric resistance heating. This means your grow rooms stay dry, and your operations stay lean.

With smaller units, you can turn on just what you need, exactly when you need it, without overloading a single system.

Dan Dettmers

Senior Application Engineer

The Distributed System Advantage

One major benefit of Quest’s dehumidifiers is their distributed system approach. Rather than relying on one or two large rooftop units to manage your entire grow room’s climate, Quest offers a more efficient, flexible solution.

By distributing smaller units throughout the grow space, you gain better control, redundancy, and flexibility. If one unit fails, the others continue running, preventing costly downtime or plant damage.

“Think of it like a fleet of small trucks versus one giant dump truck,” Dan explains. “With smaller units, you can turn on just what you need, exactly when you need it, without overloading a single system.”

This distributed approach ensures more consistent environmental control and lower energy consumption.

Efficient systems aren’t just good for your plants—they’re good for your bottom line

Dan Dettmers

Senior Application Engineer

Bottom Line: It’s About Long-Term Savings

While the initial cost of installing an efficient dehumidification system may seem high, it’s an investment in your operation’s future. Quest’s systems not only reduce energy consumption, but they also qualify for energy rebates in states like Oregon, Michigan, and California. These rebates can significantly offset your equipment costs—sometimes even covering the full amount.

“Efficient systems aren’t just good for your plants—they’re good for your bottom line,” Dan adds.

You need the right tools for the job

Dan Dettmers

Senior Application Engineer

Get Smart About Reheat

Reheat, at its core, is simple: cool the air to remove moisture, then reheat it to optimal temperatures. But the challenge is doing it efficiently and effectively—and that’s where Quest excels. Whether you’re a small-scale legacy grower or managing a large commercial operation, Quest’s dehumidifiers help save money, boost efficiency, and maintain optimal grow room conditions.

If you’re serious about optimizing your operation, it’s time to stop wasting energy and start thinking smart. When it comes to reheat, Quest has the tools you need.

Want to learn more?

Contact Quest today to discover how our efficient dehumidification systems can benefit your grow operation—and your bottom line.

Published on May 29 2025

Categories: Climate Control, Dehumidification, Efficiency, Grow Room Setup, News, Sustainability