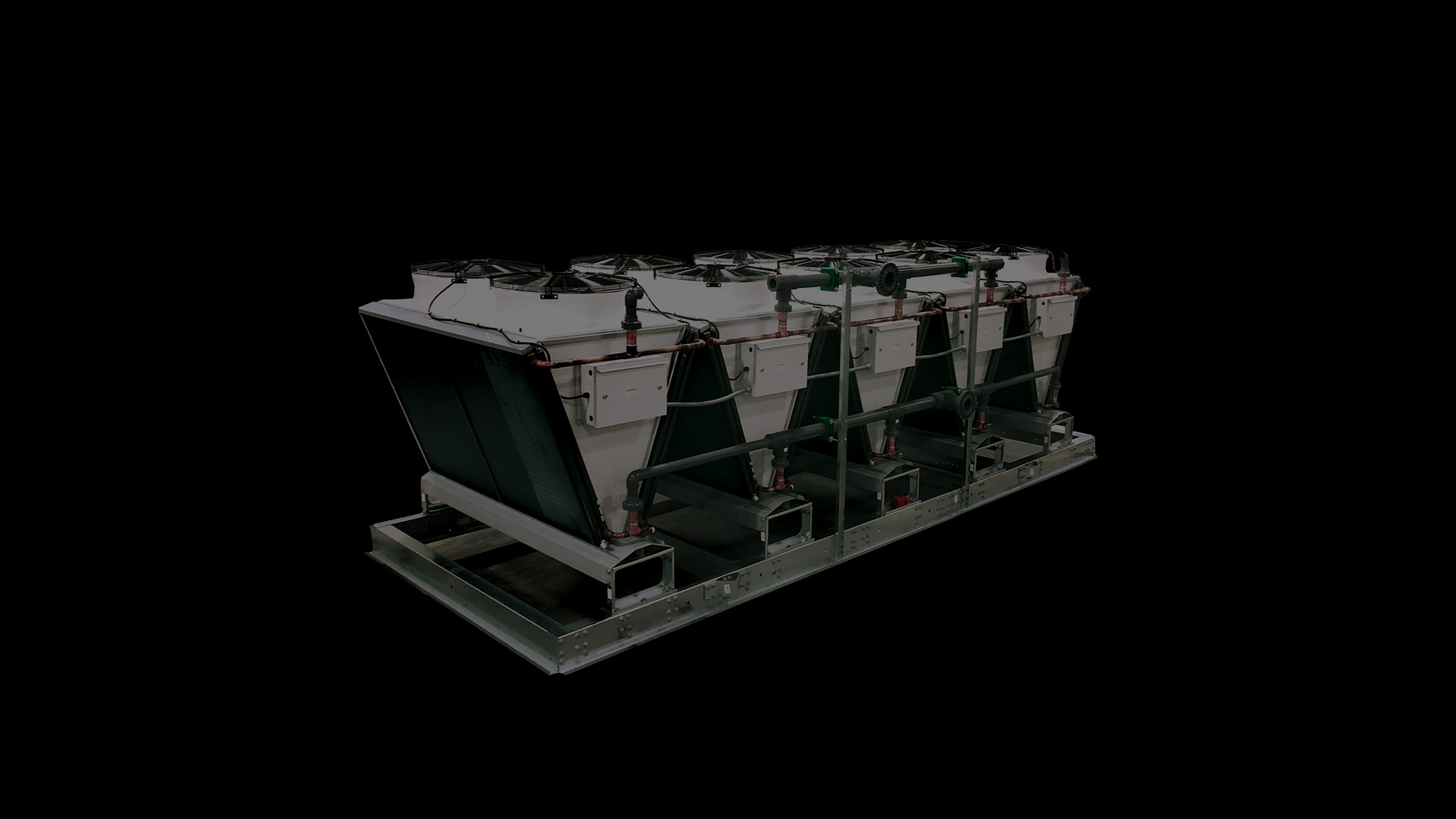

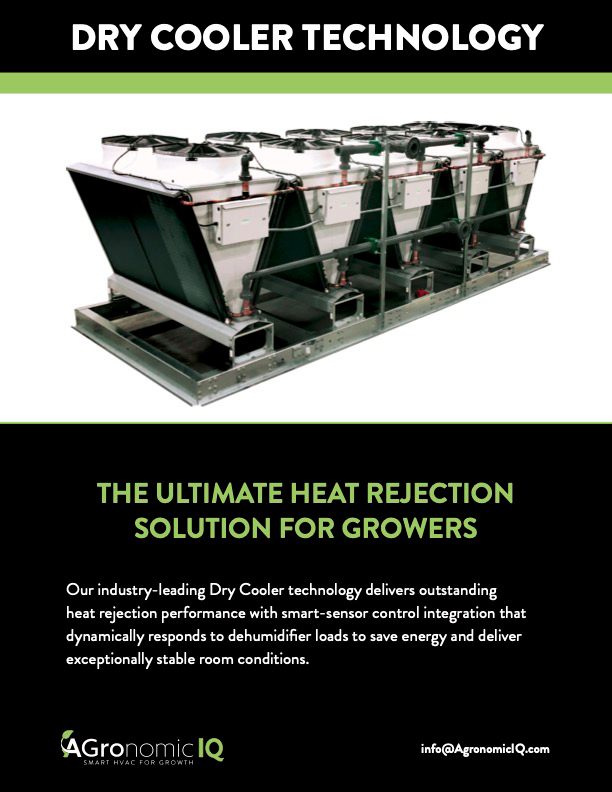

THE ULTIMATE HEAT REJECTION SOLUTION FOR GROWERS

Our industry-leading Dry Cooler technology delivers outstanding heat rejection performance with smart-sensor control integration that dynamically responds to dehumidifier loads to save energy and deliver exceptionally stable room conditions.

AGronomic IQ’s Advanced Dry Cooler Heat Rejection Technology

Length: 02:52

- Why dry coolers?

- Decoupling refrigerant from heat exchange is a huge advantage

- Eliminates any and all issues related to traditional refrigerant heat exchange

- Wide range of dry cooler combinations and size capacities, EC fans

- Individual pump kits, plus (new) dual pumps for additional redundancy

State-of-the-art technology

Our proprietary, custom-designed dry coolers use a water-glycol fluid mix to reject heat outdoors, thereby reducing expensive refrigerant use by more than 85%. With smart-sensor communication, our dehumidifiers provide optimal performance synchronization to efficiently match heat rejection loads and maintain stable room conditions, while conserving energy.

For the indoor grow industry, using a glycol fluid mix as a secondary heat exchange fluid not only increases system reliability, but it also reduces the crop-killing risks associated with refrigerant leaks as well as the exorbitantly high cost of refrigerant replacement. It also completely eliminates the traditional risks associated with low ambient temperature that debilitate traditional refrigerant systems.

The result

The most flexible, scalable, energy-efficient, and redundant heat rejection system in the industry – with the simplest and lowest cost of installation.

Ultra quiet, low maintenance

Our fans are the quietest in the business, employing EC motors for bulletproof performance and dynamic fan speeds that adapt precisely to load demands to conserve energy and minimize on-off fan wear and tear.

Virtually maintenance-free, our coils have an epoxy-based hydrophobic coating to inhibit dust and bacterial accumulation and deliver extraordinary life expectancy.

Built-in dual pump package redundancy

Each dry cooler features a built-in dual pump package for redundancy. Using multiple independent dry coolers in series provides yet another level of both redundancy and energy efficiency with truly scalable demand-based performance.

Utilizing only PVC piping to connect to the dehumidifier, installation is easy and inexpensive. Our dry cooler technology also allows virtually unlimited line length from the dehumidifier.

Features

- Sophisticated smart-sensor-integrated outdoor heat rejection technology

- Maximum efficiency with eco-friendly 85% reduction in refrigerant charge

- Ultra-quiet, energy-efficient fan designs that modulate 0-100%

- Specially coated outdoor coils stay clean and virtually eliminate corrosion

- High-performance twin 4-row coils for maximum heat rejection and durability

- Built-in pump package with dual pumps for built-in redundancy

- Modular V-shaped design for minimum fluid pressure drop and peak efficiency

- Multiple module configurations for scalability, efficiency, and redundancy